Anyone, anywhere who enjoys world cuisines will have a bottle of soy sauce in their kitchen cupboards. We are all used to using soy sauce in our cooking and splashing it over our fried rice dishes…. It adds that fantastic ‘umami’ flavour to sauces, casseroles, marinades, even dressings – but what actually is it? We had so many people asking us over the years, we thought we’d take you on a tour of the factory where some of most popular soy sauce products are made. Yugeta Shoyu make our own label Organic Soy Sauce and Yuzu Soy Sauce plus chef's favourites Nama Shoyu - fresh (unpasteurised) double fermented soy sauce and Smoked soy sauce.

When we are talking about soy sauce at The Wasabi Company – we aren’t really talking about the stuff you’ll find in the supermarket or that most likely comes with your sushi delivery because at The Wasabi Company everything is a little bit special. If you’ve tried any of our products, you probably know that already. We supply some of the top chefs and restaurants in the UK and Europe and now these products are available to foodies at home through our online store.

Our Own Label Organic Soy sauce and Yuzu Soy sauce are made by the Yugeta family in the traditional way, no shortcuts and only the purest of ingredients. Known in Japan as one of the finest soy sauce (shoyu) producers, the same family have been making soy sauce over 4 generations, passing down knowledge and expertise since 1923. Their factory sits just outside Tokyo in a village called Tawame in Saitama Prefecture.

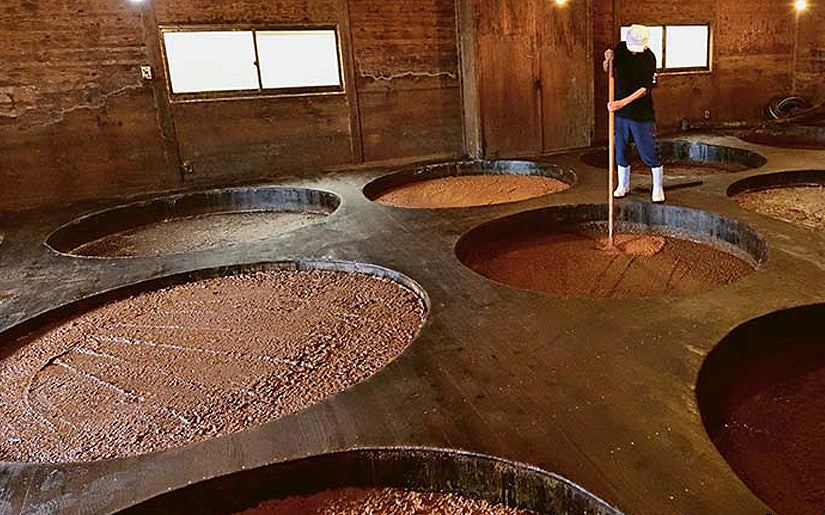

Yugeta Shoyu’s soy sauce is brewed naturally and uses Japan-grown wheat and soya beans; koji mould, sun-dried salt and water from their well, which is fed by flow from the Chichibu mountain range. Yugeta san ages the soy sauce moromi (malt or mash) for many of his types of shoyu in cedar barrels, some are over 100 years old.

This gigantic barrel is called the '20 koku barrel’. It has a capacity of about 3600l, with a diameter of 1.7m and a height of 2.0m. Nowadays there are only a few craftsmen alive who can make these incredible barrels.

Let’s take a look at the process of how soy sauce is made at the Yugeta factory in Tawame.

Koji (Aspergillus oryzae) is added to steamed soya beans and roasted wheat. The temperature in the room is set at 30C and 100% humidity. The koji mould is allowed to grow for 3 days to create ‘koji’ or malt. The koji is then moved to the cedarwood barrels where it is mixed with salted water. This ‘Moromi’ mash is then left to ferment and mature for a minimum of one year. Once the soy is judged to be ready it is pressed, filtered and bottled.

The Yugeta family are so proud of their traditional techniques that you can actually take a tour of the factory and see the process for yourself if you visit Japan! In the observation room you can feel and smell the scent of soy sauce product, watch the soybeans being steamed and the wheat being roasted. You can observe the soy sauce pressing and in the café, you can taste the wonderful soy sauces through a variety of foods such as soy sauce marinated pork dumplings and wonderfully rich soy sauce ice cream.